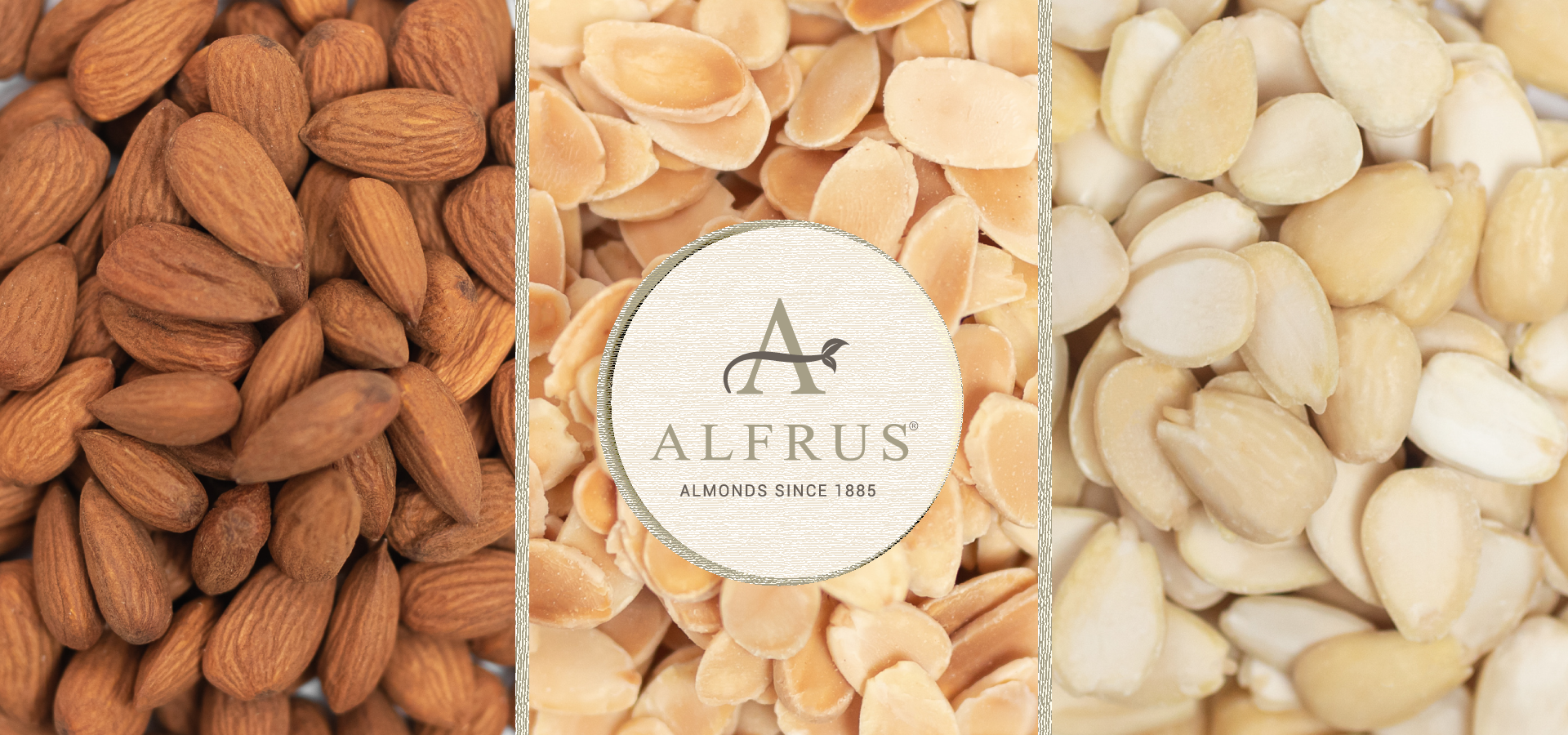

Natural, roasted or blanched? Which almond type best enhances your product?

In the food & beverage sector, every detail makes a difference, starting with raw ingredients. Almonds, a key component in countless sweet and savory preparations, are no exception: each variety and processing method affects the flavor, texture, product stability, and even the perception of the end consumer. Each almond type is therefore more suitable for specific market segments and applications.

At Alfrus, we have built our expertise on this principle: offering a complete range of almond processing options, including natural, blanched, and roasted almonds, available in various formats, from sticks and diced almonds to flour and marzipan, to meet the needs of ice cream parlors, bakeries, confectionery industries, and food processing companies. We ensure consistent quality, supply chain safety and a sensory profile tailored to the intended use.

Natural almonds: the essence of purity

Natural almonds are the closest to the original fruit, undergoing only cleaning, optical sorting, and sizing, while maintaining their characteristic skin. This choice preserves not only their rustic appearance and full flavor, but also their nutritional profile, thanks to the polyphenols and fibers contained in the skin.

Most common uses include:

- Health-conscious snacks and functional foods (energy and protein bars)

- Brands with a “plant-based” and “clean label” focus

Blanched almonds: delicacy and uniformity

Blanched almonds are obtained through a thermal process involving immersion in boiling water. This allows the natural removal of the skin without compromising seed quality or requiring chemical treatments. The result is a versatile almond with a uniform and clear color and a sweeter, softer, and more delicate flavor: an ideal neutral base for high-precision processing.

Key applications include:

- Premium pastry and chocolate production (flours, creams, fillings)

- Ice cream, frozen desserts, spreads

Roasted almonds: intensity and crunchiness

Roasting is a controlled thermal process carried out in a four-stage oven, and it can be tailored to customer specifications. This process enhances aromatic notes of caramel and hazelnut, delivering a crunchy texture and making almonds the star ingredient in high-sensory-impact products.

Roasting also improves food safety by reducing internal moisture, creating an environment less favorable to microbial growth. Additionally, it inactivates enzymes responsible for internal degradation processes, extending the product’s shelf life and stability.

Most common uses include:

- Ice creams and sweet snack industries (toppings, bars, ready-to-eat snacks)

- Gourmet products (chocolates, pralines, nougat, premium bars)

- Baked goods and cookies

At Alfrus, we offer an extensive catalog of processing methods and formats, supported by our technical expertise and know-how. Our team works closely with client companies to identify the most suitable almond format and processing method, depending on the final product and production process, ensuring consistent performance in terms of flavor, texture and stability.

Because every almond plays a specific role in shaping the final product and the sensory experience it delivers to the consumer.

28th July 2025